Rubber bellows are vital parts of industrial systems because they provide the necessary flexibility to control vibrations, motions, and thermal expansion. These bellows are made of durable rubber materials and have complex convolutional designs that enable them to absorb axial, lateral, and angular movements efficiently. Their main purpose is to reduce stress and strain by offering a flexible connection between different piping components and mechanical equipment. This capability is especially important in sectors where temperature swings and mechanical vibrations are frequent, such as HVAC, petrochemical, and power generating.

Rubber bellows manufactured by Custom Rubber Bellows are essential for maintaining the systems’ integrity, guaranteeing continuous functioning, and averting possible harm. Their adaptability and durability render them invaluable in a variety of industrial settings, with the potential to maintain operational effectiveness and prolong the life of vital machinery. The need for creative rubber expansion bellows keeps growing as industries change, propelling constant improvements in design, materials, and manufacturing techniques. In the dynamic world of industrial operations, knowing their importance is critical to maximizing performance, reducing downtime, and improving overall system reliability.

1. Rubber Expansion Bellow Enhancing Flexibility in Piping Systems

Rubber bellows, which provide unmatched flexibility to handle movement, vibration, and thermal expansion, are essential for pipe systems. These bellows, usually constructed of premium rubber materials, are intended to absorb axial, lateral, and rotational movements, lowering the stress on equipment and pipes. Rubber expansion bellows guard against thermal expansion and contraction damage, which can result in leaks, cracks, and structural failures by offering a flexible connection between pipe components.

They are perfect for a wide range of industrial applications because of their resistance to different working circumstances, including as temperature changes and chemical exposure. Rubber bellows are utilized in power generation facilities, petrochemical plants, and HVAC systems, and they are essential to maintaining the longevity and integrity of pipe systems.

2. Expansion Bellows Mitigating Stress in Mechanical Systems

Because they offer flexibility to absorb thermal expansion and contraction, expansion bellows, also known as compensators or expansion joints, are crucial parts of mechanical systems. These bellows successfully reduce stress and vibration in pipes, ducts, and equipment because of their convolutions, which provide axial, lateral, and rotational movement. Expandable bellows are frequently employed in industrial settings to offset thermal expansion in pipelines, lowering the possibility of damage and early failure.

Rubber, metal, and cloth can all be used to build bellows, depending on the application’s specifications. Rubber bellows in particular are ideal for difficult operating circumstances because of their exceptional resistance to abrasion, corrosion, and environmental variables. Bellows enhance the dependability and effectiveness of mechanical systems in various sectors by allowing for movement and reducing stress.

3. Expansion Bellows Rubber Versatile Sealing Solution

Expanded bellows rubber provides flexible and adaptable sealing solutions for various industrial uses. These bellows offer exceptional resistance to heat, chemicals, and climatic conditions. They are usually made of premium rubber materials like silicone, neoprene, or EPDM. To minimize damage and guarantee trouble-free operation, expansion bellows rubber is made to absorb thermal expansion and contraction in mechanical equipment, HVAC ducts, and pipe systems.

By accommodating axial, lateral, and angular movements, their robust and flexible structure lessens the strain on linked components. The integrity and dependability of systems are greatly enhanced by using expansion bellows rubber, which is utilized in power plants, chemical processing facilities, and marine applications. Expandable bellows rubber choices are widely available from manufacturers to satisfy specialized application needs. Custom designs catered to particular operating circumstances are among the options available.

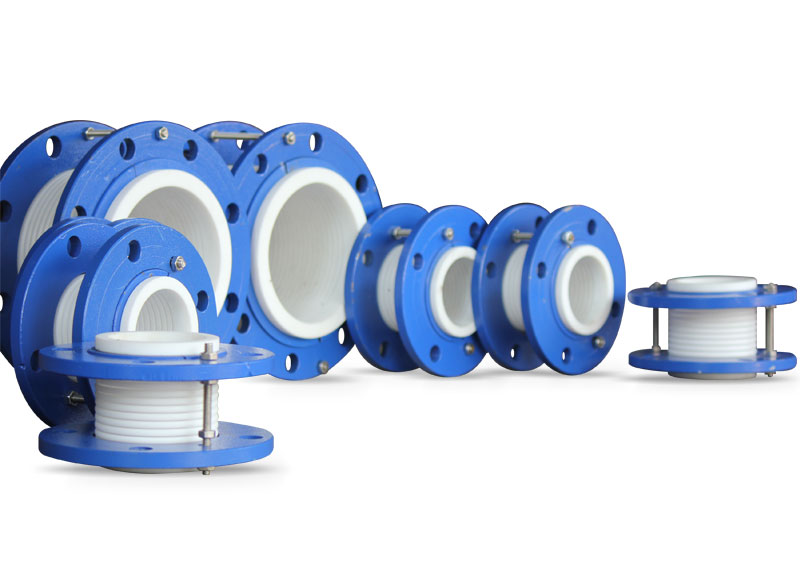

4. Flange Bellows Provides Reliable Sealing and Flexibility

Specialized expansion joints called flange bellows are utilized in plumbing systems to offer flexible and dependable sealing at flanged connections. These bellows’ flexible, corrugated construction allows for axial, lateral, and rotational movement, effectively compensating for vibration and thermal expansion. Installed between flanges in pipelines, pumps, and valves, bellows offer a leak-proof seal that can withstand movement and misalignment.

They are commonly used in scenarios where rigid piping connections are impractical or prematurely fail. Bellows, made of rubber, metal, or cloth, provides exceptional resistance to abrasion, corrosion, and temperature fluctuations, guaranteeing long-term dependability under challenging conditions. Bellows are essential to preserving the integrity and functionality of pipe systems in various sectors because of their capacity to absorb movement and reduce stress on related components.

5. Rubber Expansion Bellows Ensures Durability and Performance

Industrial plumbing systems require expansion bellows because they offer dependable, flexible, and long-lasting performance. These bellows, usually constructed from premium rubber compounds, are ideal for various applications because of their exceptional resistance to abrasion, corrosion, and climatic conditions. Rubber expansion bellows are intended to cushion the stress on linked components and stop leaks or damage by absorbing thermal expansion and contraction in pipe systems.

Their pliable, corrugated design permits angular, lateral, and axial movement, guaranteeing seamless functioning and lowering the possibility of early failure. Rubber bellows are essential for preserving piping systems’ dependability and integrity, whether utilized in water treatment facilities, chemical processing plants, or HVAC systems. Rubber bellows manufacturers provide a range of choices, including custom designs suited to particular working circumstances, to satisfy the demands of individual applications.

Conclusion

In summary, rubber bellows play a critical role in preserving the efficiency and operational integrity of industrial systems, making them essential components. By accommodating motions, vibrations, and thermal expansion, they reduce the chance of damage and downtime and guarantee the seamless operation of mechanical equipment and piping systems. Rubber bellows are an essential component of many industries, including HVAC, petrochemical, and power production, as they safeguard crucial infrastructure and guarantee continuous operation. These bellows are quite useful because of their adaptability and durability, which allow them to resist challenging circumstances and settings.

Innovative rubber bellows will always be in demand as long as industries and technologies keep changing. In order to satisfy changing industry requirements and demands, manufacturers are constantly working to improve design, materials, and manufacturing techniques. Using rubber bellows, companies can enhance system reliability, save maintenance expenses, and maximize performance. Rubber bellows continue to be vital parts of the dynamic industrial environment because they offer the flexibility and toughness needed to keep critical systems operating at peak performance. Since they maintain the durability and integrity of the global industrial infrastructure, their importance cannot be emphasized.