Across different regions, the Ethylbenzene market followed similar price trajectories to its Ethylene and Benzene feedstocks in H1 2023. In Asia, initial high prices in January were driven by post-lockdown Chinese production, yet oversupply and reduced chemical industry demand led to a downward trend for the rest of Q2. Europe experienced a parallel scenario, with added influence from elevated crude oil prices due to energy supply disruptions. North America exhibited flattened, fluctuating prices based on downstream needs and feedstock costs, maintaining overall market stability.

Request Free Sample – https://www.procurementresource.com/resource-center/ethylbenzene-price-trends/pricerequest

Definition

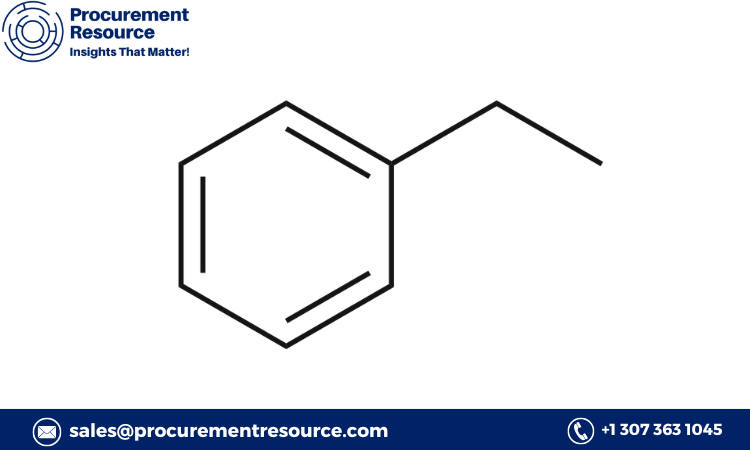

Ethylbenzene is a hydrocarbon compound with the chemical formula C8H10. It is a colourless liquid with a sweet, aromatic odour. It is primarily used as a precursor in the production of styrene, a crucial building block for plastics and synthetic rubber. Ethylbenzene also finds applications as a solvent and in the manufacture of various chemical products.

Key Details About the Ethylbenzene Price Trend:

The price trend of ethylbenzene, a key industrial chemical primarily used in the production of styrene, can be influenced by various factors. Here are some key details about the ethylbenzene price trend:

-

Feedstock Prices: Ethylbenzene is typically produced from benzene and ethylene. Fluctuations in the prices of these feedstocks can directly impact the cost of ethylbenzene production and consequently its market price.

-

Demand for Styrene: Since ethylbenzene is a precursor to styrene, the demand for styrene can have a significant impact on the ethylbenzene price. Styrene is widely used in the production of plastics, rubber, and resins, so trends in these industries can influence ethylbenzene prices.

-

Global Economic Conditions: Economic factors such as GDP growth, industrial output, and consumer demand can affect the demand for products that rely on ethylbenzene. Economic downturns may lead to reduced demand and lower prices, while periods of economic expansion can drive up demand and prices.

-

Supply Dynamics: Production capacity, inventory levels, and operational efficiency within the ethylbenzene industry can affect supply dynamics and consequently prices. Disruptions in production, such as plant outages or supply chain issues, can lead to temporary price increases.

-

Regulatory Changes: Environmental regulations, trade policies, and health and safety standards can impact the production, transportation, and use of ethylbenzene, potentially affecting its price.

-

Energy Prices: Ethylbenzene production is energy-intensive, so fluctuations in energy prices, particularly those of crude oil and natural gas, can influence production costs and ethylbenzene prices.

-

Market Speculation: Like many commodities, ethylbenzene prices can also be influenced by speculative trading activities in futures markets, where traders bet on future price movements based on various factors including supply, demand, and geopolitical developments.

Monitoring these factors can provide insights into the ethylbenzene price trend and help stakeholders in the chemical industry make informed decisions regarding production, procurement, and investment.

Industrial Uses Impacting the Ethylbenzene Price Trend:

The price trend of ethylbenzene, a key industrial chemical, can be influenced by various factors related to its production, demand, and market dynamics. Here are some industrial uses that can impact the price trend of ethylbenzene:

-

Styrene Production: One of the primary uses of ethylbenzene is as a precursor in the production of styrene, which is further used in the manufacture of various plastics, rubber, and resins. Any fluctuations in the demand for styrene can directly affect the demand for ethylbenzene and subsequently its price.

-

Polystyrene Production: Polystyrene, a derivative of styrene, finds extensive application in packaging, consumer goods, and construction materials. Changes in the demand for polystyrene can have a ripple effect on the demand for ethylbenzene and its price.

-

Rubber Production: Ethylbenzene is also used in the production of synthetic rubber, particularly styrene-butadiene rubber (SBR). The demand for SBR, which is widely used in tire manufacturing and other automotive applications, can influence the ethylbenzene market.

-

Paints and Coatings: Ethylbenzene is utilized as a solvent in the formulation of paints, coatings, and varnishes. Fluctuations in the construction and automotive sectors, which are major consumers of paints and coatings, can impact the demand for ethylbenzene.

-

Pharmaceuticals: While not as significant as its usage in the production of plastics and rubber, ethylbenzene is also used in the synthesis of pharmaceuticals and agrochemicals. Changes in the pharmaceutical industry, including shifts in demand for specific drugs or changes in regulations, can affect the ethylbenzene market to some extent.

-

Other Chemicals: Ethylbenzene is a precursor in the production of various other chemicals like ethylphenol, acetophenone, and ethyl acetate. Any changes in the demand for these downstream chemicals can indirectly impact the ethylbenzene market.

-

Feedstock Prices: The price of ethylbenzene can also be influenced by the cost of its feedstock, namely benzene and ethylene. Fluctuations in the prices of these raw materials, which can be influenced by factors such as crude oil prices, supply-demand dynamics, and geopolitical factors, can affect the overall production cost and consequently the price of ethylbenzene.

-

Regulatory Factors: Changes in regulations related to environmental standards, health, and safety regulations, or trade policies can also impact the production, distribution, and pricing of ethylbenzene.

Understanding these industrial uses and their respective market dynamics is essential for assessing the factors driving the price trend of ethylbenzene. Additionally, macroeconomic factors, geopolitical events, and technological advancements can also play a role in shaping its price trajectory.

Key Players:

- Dow Chemical Company

- XX Mobil Corp

- Jx Nippon Oil and Energy group

- Royal Dutch Shell Plc

- Tianjin Jixin Industrial & Trade Co., Ltd.

- Zhejiang Weishi Biotechnology Co., Ltd

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA